Why is working with a "transparent and troublesome" partner far more effective in ensuring the success of your mid- to high-end projects than with a "silent and smooth" factory?

When sourcing custom lighting, are you tired of this cycle: seemingly smooth communication, tempting quotes, only to be met with unexpected quality disasters on site?

This isn't accidental. It's the inevitable price of mistaking "complex customization" for "simple procurement."

We offer a completely different model. We firmly believe that the true cost isn't the price you pay for high quality, but the price you pay for low quality.

1, in the customization industry, quality isn't simply "good when it leaves the factory." It's a system that permeates everything:

Design Quality:

Factory Model: "Build to the drawing, drawing errors are not our responsibility."

Our Model: We are an extension of your technology. We thoroughly review, question, and work with you to optimize every detail to ensure the drawings are executable and meet the end-use scenario.

Process Quality:

Single-factory Model: "Black box" production, reporting good news but not bad news.

Our Model: Transparent Project Management. You'll receive feedback at key milestones (such as material confirmation, first sample review, and before and after electroplating) just like being in the factory. We expose problems so we can work together to eliminate them.

Product Quality:

Ordinary factory model: Meet "factory standards."

Our model: Meet "project success standards." We insist on a second inspection to ensure you receive a final product that's ready for delivery to the project site and withstands rigorous testing.

2, many customers ask for a "firm delivery date." We fully understand, as project schedules are closely linked.

But in the true customization industry, a seemingly "firm" delivery date given on day one is often the biggest risk.

We firmly believe that a "reliable" delivery date isn't the fastest, but rather:

One that includes a "quality buffer period"—this is because we insist on conducting more rigorous internal inspections before shipment and allow time for necessary adjustments.

A dynamically managed, synchronized delivery schedule—when encountering unique color challenges or material processing bottlenecks (which are common in custom production), we provide immediate warnings and solutions, rather than silently waiting for delays.

A delivery schedule focused on project success—we would rather notify you of a new, delayed date due to rework than ship products with obvious defects to your project site on time.

We don't promise you the fastest shortcuts, but we can promise: we won't leave you facing risks in the dark. Through transparent project management, we ensure that every date you see is based on the most realistic current situation.

This is the most reliable promise we can offer.

Why multi-stakeholder projects rush timelines but delay decisions

Why multi-stakeholder projects rush timelines but delay decisions

Layered Lighting 101: The Fastest Upgrade That Changes a Home

Layered Lighting 101: The Fastest Upgrade That Changes a Home

The Real Cost of Lighting Delays: It’s Not the Fixture, It’s the Coordination

The Real Cost of Lighting Delays: It’s Not the Fixture, It’s the Coordination

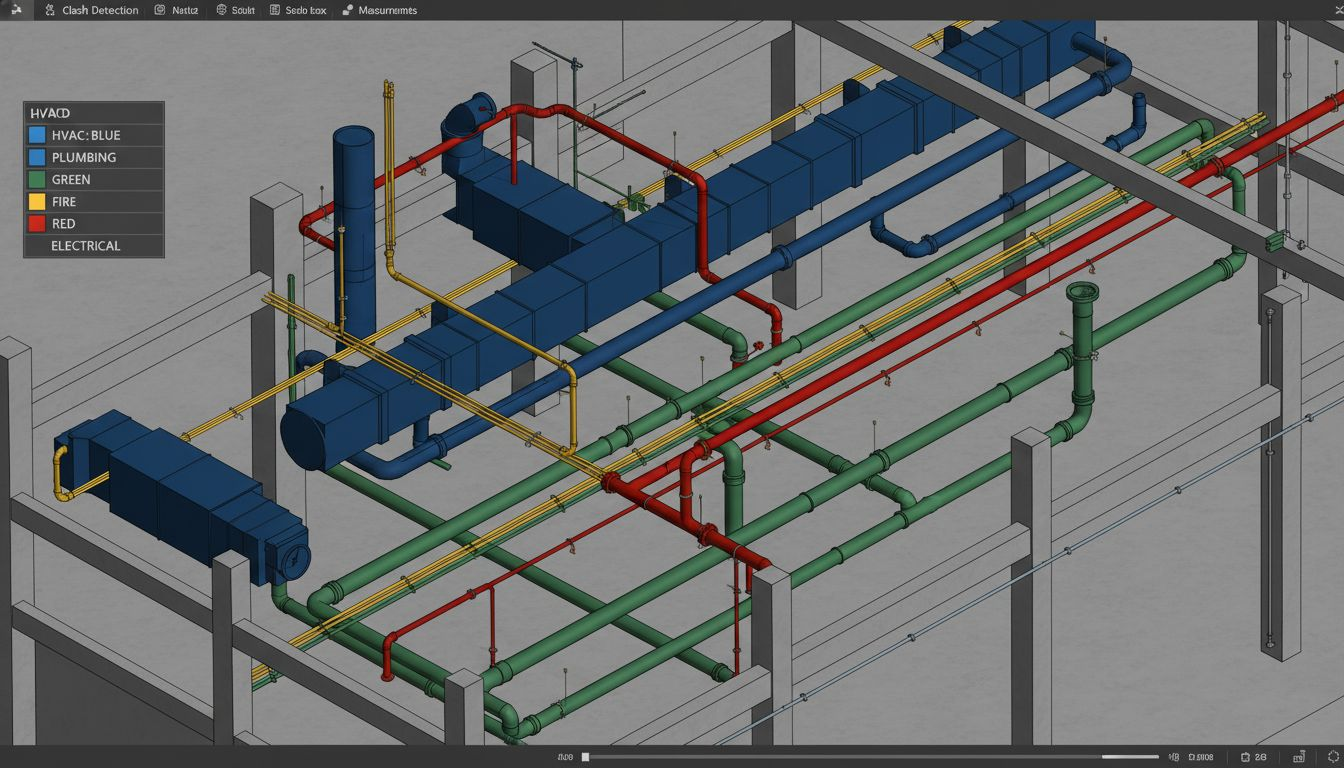

From Vision to Handover: A Complete Guide to Commercial Lighting Design Process

From Vision to Handover: A Complete Guide to Commercial Lighting Design Process