The Technical Buyer's Guide: Materials, Optics & Specs for Durable Bollard Lights

The Technical Buyer's Guide: Materials, Optics & Specs for Durable Bollard Lights

Selecting bollard lights for a project that must last for decades requires moving beyond aesthetics to the core of engineering and performance. This guide decodes the critical specifications that separate commercial-grade fixtures from consumer products, ensuring you invest in lighting that delivers on safety, longevity, and design intent.

1. Housing Materials: The Foundation of Longevity

The choice of material determines a fixture's resistance to corrosion, physical impact, and aesthetic aging.

Die-Cast Aluminum (Powder-Coated): The industry benchmark. Aluminum offers an exceptional strength-to-weight ratio, excellent heat dissipation for LEDs, and inherent corrosion resistance. A high-quality thermoset polyester powder coating is essential, providing a uniform, UV-stable finish in any RAL color. It protects against chips, scratches, and fading.

Stainless Steel (Grade 304 or 316): The premium choice for extreme environments, particularly coastal areas with salty air. Grade 304 offers excellent general corrosion resistance, while Grade 316 (marine-grade) contains molybdenum for superior resistance to chlorides. Finishes range from brushed satin to mirror polish, developing a distinguished patina over time.

Architectural Concrete & Engineered Polymer: Used for a modern, monolithic look. High-density concrete or mineral-filled polymers provide massive durability and UV stability. These materials are often integrally colored, eliminating concerns about finish wear.

2. The Optical System: Engineering Light Distribution and Comfort

How light is emitted is as important as how much. A quality optical system ensures visual comfort and task effectiveness.

Lens Material:

Toughened (Tempered) Glass: Offers superior clarity, scratch resistance, and a premium feel. It maintains its appearance over time.

Polycarbonate: Extremely impact-resistant (virtually unbreakable) and lighter. High-quality versions include UV-inhibiting coatings to prevent yellowing.

Light Distribution & Glare Control: Not all bollards create the same light pattern.

Symmetric Distribution: Casts a circular pool of light, ideal for marking points or general area illumination.

Asymmetric Distribution: Directs light primarily in one direction (e.g., a “side-emitting” pattern). This is crucial for pathway lighting, as it throws light across the walking surface rather than wastefully into the sky or surrounding foliage.

Glare Control: This is achieved through deeply recessed LED modules, internal baffles, and micro-prismatic or opal diffusers that soften the light source. The goal is a high Visual Comfort Probability (VCP) and low Unified Glare Rating (UGR), ensuring the fixture is comfortable to look at, not just look from.

3. Decoding the Specification Sheet: Key Performance Metrics

Understanding these terms is non-negotiable for professional specification.

| Specification | What It Means & Why It Matters | Minimum Recommendation for Landscape Use |

|---|---|---|

| IP Rating | Ingress Protection against solids & liquids. | IP65: Dust-tight & protected against low-pressure water jets. IP66/IP67 for flood-prone or harsh coastal sites. |

| IK Rating | Impact Protection level (EN 62210). | IK08 (resists 5 Joule impact) for public access areas. IK10 (20 Joule) for high-vandalism risk zones. |

| Luminous Flux | Total visible light output, measured in Lumens (lm). | 300-500 lm for ambient path marking; 700-1200 lm for area/security lighting. |

| Correlated Color Temperature (CCT) | The perceived “warmth” or “coolness” of white light, in Kelvin (K). | 2700K-3000K (Warm White) for hospitality, residential. 3000K-4000K (Neutral White) for civic, corporate settings. |

| Color Rendering Index (CRI) | Accuracy of color reproduction under the light. | CRI >80 is standard. CRI >90 (or Ra9 >50) is recommended where true color perception matters (e.g., gardens, facade lighting). |

| Lumen Maintenance (Lx) | Predicts lifespan. L70 = time until output depreciates to 70% of initial. | L70 > 50,000 hours for quality LEDs. L90 > 50,000 hours indicates a superior, longer-lasting product. |

Conclusion: The Sum of Its Specs

A commercial-grade bollard light is the sum of its rigorously defined parts. By specifying the right material for the environment, the correct optical system for the task, and verifying performance through standardized metrics, you secure an asset—not an expense. This technical diligence ensures the lighting will perform reliably, maintain its appearance, and fulfill its design purpose for the long term, with minimal operational cost and disruption

Why multi-stakeholder projects rush timelines but delay decisions

Why multi-stakeholder projects rush timelines but delay decisions

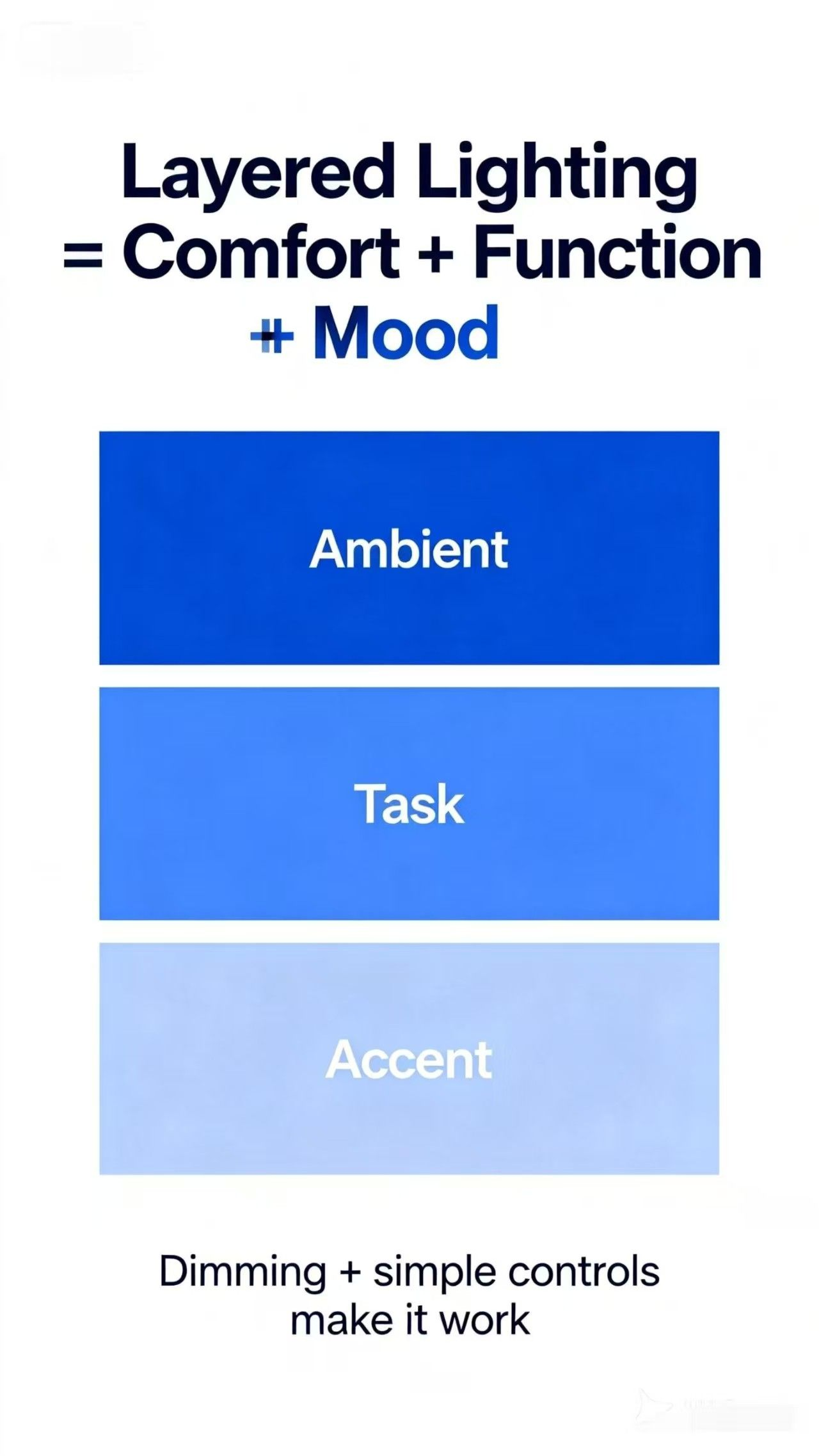

Layered Lighting 101: The Fastest Upgrade That Changes a Home

Layered Lighting 101: The Fastest Upgrade That Changes a Home

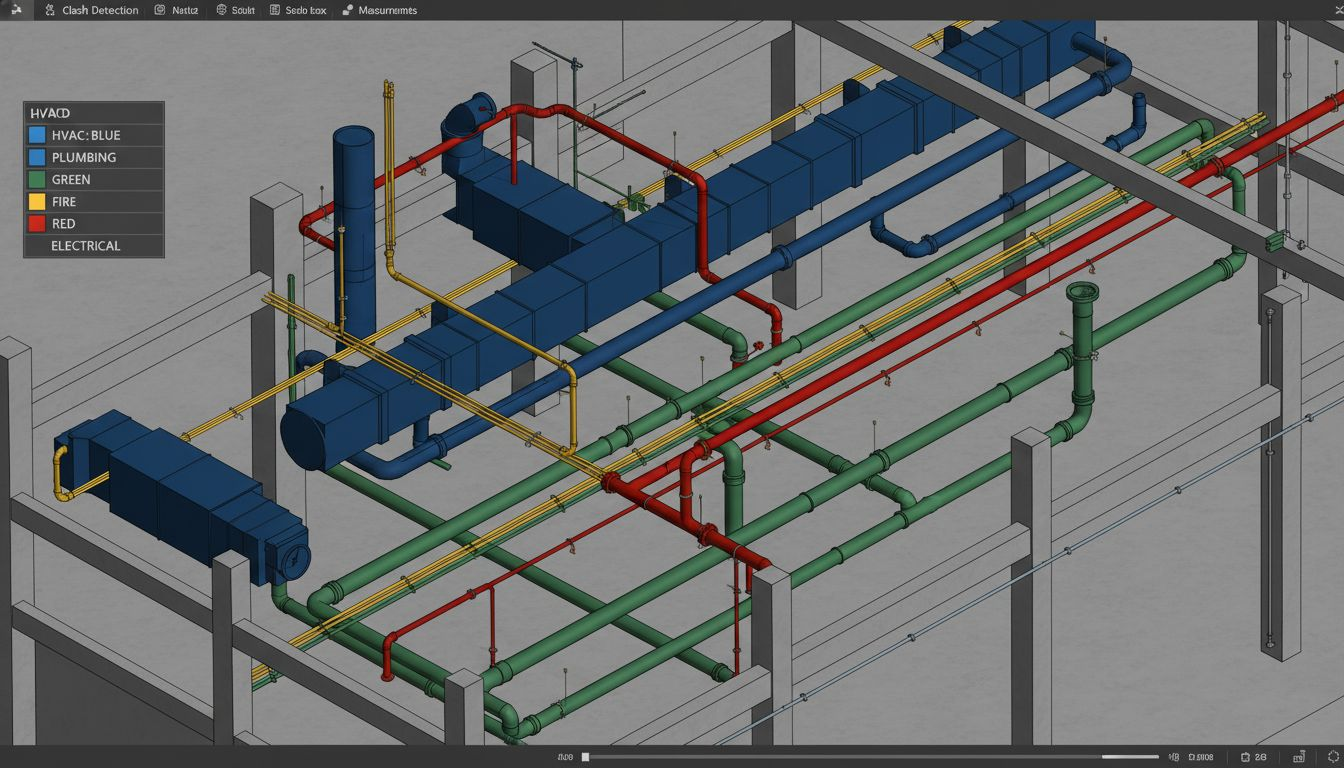

The Real Cost of Lighting Delays: It’s Not the Fixture, It’s the Coordination

The Real Cost of Lighting Delays: It’s Not the Fixture, It’s the Coordination

From Vision to Handover: A Complete Guide to Commercial Lighting Design Process

From Vision to Handover: A Complete Guide to Commercial Lighting Design Process